Homes with little ones are full of energy, curiosity, and a lot of chaos. While toddlers explore the world by touching, tasting, and poking everything they can reach, electrical systems should be left well alone. Exposed cords, damaged wiring and wet surfaces can turn a normal day into a stressful one.

By following these steps, you can keep your little ones and your home safe from the hazards of electrical accidents.

Securing Outlets and Cords: Preventing Curious Explorers from Danger

One of the first places kids’ hands reach for is the wall. Here’s what you can do to prevent any dangerous accidents:

Outlet covers: These are small plastic plugs that fit into unused sockets. They’re cheap, easy to install, and stop little fingers from poking into places they shouldn’t.

Sliding or spring-loaded outlets: Some homes now have outlets that automatically close when nothing is plugged in. This is a great upgrade if you will be so rushed off your feet that you might forget to cover the sockets.

Hide and secure cords: Cables running across floors aren’t just a trip hazard; they’re too inviting to young, curious minds. Bundle cords together, run them along walls, or use cord covers. Out of sight often means out of reach.

Check for wear and tear: Frayed cords or damaged plugs are more than an eyesore; they’re a real risk to anybody, but especially little bodies. Keep your children well away and replace them as soon as you spot a problem.

Teaching kids never to touch plugs or cords without permission is useful, but it’s a lot safer to physically block their access.

Addressing Water and Appliance-Related Hazards

We all know toddlers are curious, and water plus electricity is like a magnet for trouble. Even a little splash near a plug or appliance can be dangerous.

Here are some practical steps you can take to protect your little ones from harm:

Keep appliances away from sinks and baths: Hair dryers, kettles, or toasters near water are asking for trouble. Make it a rule that anything electrical stays well clear of wet areas, as well as little fingers and hands.

Unplug unused appliances: This not only saves electricity but also removes temptation for children who may be tempted to play with them.

Use GFCI outlets in wet areas: Ground Fault Circuit Interrupters (GFCIs) are outlets that automatically cut the electricity if water is detected. They’re common in kitchens, bathrooms, and laundry areas, and they save lives.

Supervise during use: Even with precautions, kids around running appliances need supervision. In a split second, your child could be climbing onto the kitchen counter to grab the toaster.

Essential Home Safety Upgrades and Professional Checks

Making a home child-safe isn’t just about quick fixes. Getting a professional in to upgrade your safety features and check your system will provide long-term protection and peace of mind.

Child-proof power points: Consider asking your electrician to replace older outlets with child-resistant versions throughout your home to make it harder for them to play with.

Switchboards and wiring: An electrician can check your home’s wires and power board to make sure they are safe and strong enough for all the devices your family uses.

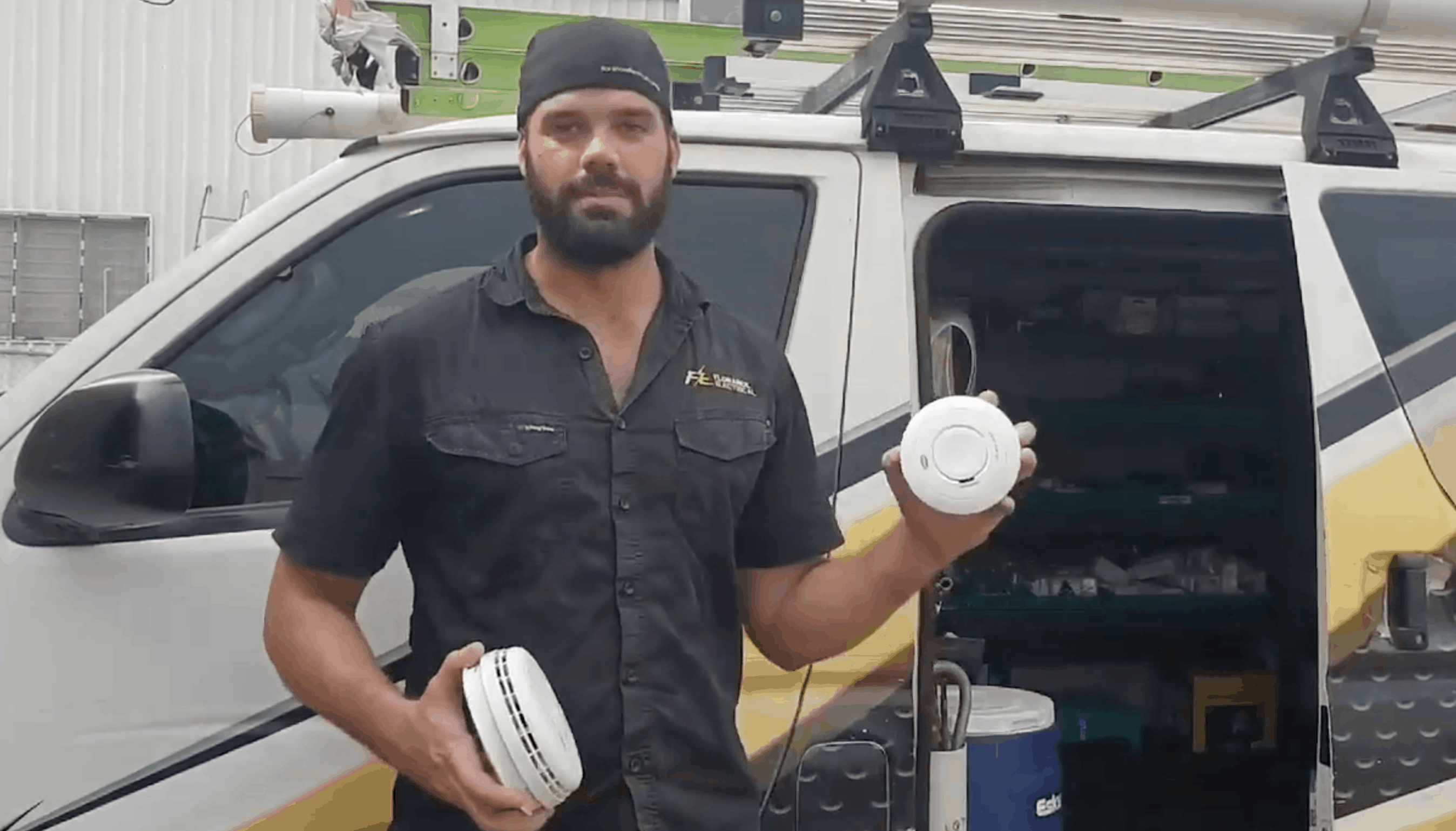

Smoke alarms and surge protection: These aren’t just “nice extras.” Smoke alarms alert you to fire risks, and surge protection keeps appliances safe from system overloads that could cause accidents or fires.

Regular inspections: Even if everything looks fine, a licensed electrician can spot hidden hazards like loose wires or overloaded circuits before they become a problem.

Safety upgrades are one of the best investments in your family’s safety that you can make. Plus, you won’t need to explain to the kids or anyone else why a play session ended in a visit to the Emergency Department.

Keeping your home safe for young kids is about thinking about how your kids may access electrical systems and getting help from the experts when you need it. Cover outlets, keep cords tidy, make sure water and electricity don’t mix, and have your wiring checked by a professional regularly. These steps make your home much safer, so your little ones can explore without getting hurt.

For families in the Northern Territory, Florance Electrical is here to help make your home safe and child-friendly. Get in touch to book a professional check or upgrade today.